Breaking News

Iran (So Far Away) - Official Music Video

Iran (So Far Away) - Official Music Video

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Why America's Two-Party System Will Never Threaten the True Political Elites

Why America's Two-Party System Will Never Threaten the True Political Elites

Top Tech News

How underwater 3D printing could soon transform maritime construction

How underwater 3D printing could soon transform maritime construction

Smart soldering iron packs a camera to show you what you're doing

Smart soldering iron packs a camera to show you what you're doing

Look, no hands: Flying umbrella follows user through the rain

Look, no hands: Flying umbrella follows user through the rain

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

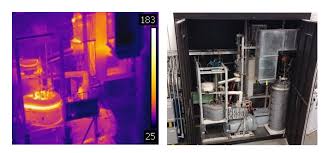

Molten salt test loop to advance next-gen nuclear reactors

As next-generation nuclear reactors, known as Gen IV power plants, are developed, it is looking more and more likely that they will be of the molten salt variety. These plants swap out radioactive fuel rods and a water-coolant system with a salt slurry mixed with nuclear fuel and offer myriad benefits over their older brethren.

Such reactors are safer than old-school nuclear power plants, for example, because they operate at much lower pressures, making structural stress and failure in the event of an accident less of an issue.

Molten salt nuclear reactors (MSR) also have unique passive methods of preventing nuclear disasters. Some plants are equipped with what's known as a "freeze plug" in the reactor chamber. In the event of a power failure, the system keeping this chunk of salt in a frozen state fails, causing the plug to dissolve. This, in turn lets the salt/fuel slurry drain passively into underground tanks where it safely cools. On the other hand, if a reactor overheats, the expansion in the slurry spreads out the nuclear fuel making it harder for fission to continue, effectively shutting the plant down.

Additionally, molten nuclear reactors are more efficient than their predecessors, and are even potentially able to use waste materials that weren't completely spent in other nuclear processes. They also produce less waste that tends to decompose faster than traditional spent fuel rods and, because of their relatively small size, then can be deployed modularly as needed.

Combating corrosion

All that being said, one of the big challenges of MSRs is that hellishly hot molten salt tends to wreak havoc with whatever it comes into contact with.

Enter the joint project between Idaho National Labs (INL), Southern Company and TerraPower. That project, known as the Molten Chloride Reactor Experiment (MCRE), achieved a major milestone just last month, when it announced that it had used a prototype furnace to create a fuel based on denatured uranium at the rate of 18 kg (39 lb) per batch. That's a far cry from the three and a half tonnes the reactor will eventually need to reach criticality, but it's a start, and the fuel is being produced with 90% efficiency

Now the MCRE project has revealed the successful completion of its Molten Salt Flow Loop Test Bed, which aims to develop a reactor that can withstand the corrosive effects of molten salt.

This closed system is made from stainless steel with a slurry of lithium chloride-potassium chloride salts inside (yes, that is indeed the whole complicated name). As the salts circulate in the system, scientists are able to adjust properties of the slurry – such as temperature – without stopping the flow. This, in effect, means that they can study next-gen nuclear fuels as they circulate in real time.