Breaking News

Powerful Pro-life Ad Set to Air During Super Bowl 'Adoption is an Option' (Video)

Powerful Pro-life Ad Set to Air During Super Bowl 'Adoption is an Option' (Video)

Even in Winter, the Sun Still Shines in These Citrus Recipes

Even in Winter, the Sun Still Shines in These Citrus Recipes

Dates: The Ancient Fertility Remedy Modern Medicine Ignores Amid Record Low Birth Rates

Dates: The Ancient Fertility Remedy Modern Medicine Ignores Amid Record Low Birth Rates

Amazon's $200 Billion Spending Shock Reveals Big Tech's Centralization Crisis

Amazon's $200 Billion Spending Shock Reveals Big Tech's Centralization Crisis

Top Tech News

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

Starlink smasher? China claims world's best high-powered microwave weapon

Starlink smasher? China claims world's best high-powered microwave weapon

Wood scraps turn 'useless' desert sand into concrete

Wood scraps turn 'useless' desert sand into concrete

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

Study Shows Vaporizing E-Waste Makes it Easy to Recover Precious Metals at 13-Times Lower Costs

Study Shows Vaporizing E-Waste Makes it Easy to Recover Precious Metals at 13-Times Lower Costs

Wood scraps turn 'useless' desert sand into concrete

This group of engineers has developed a method to transform it into a new construction material that's perfect for pavements – and it can help reduce the need to destructively extract sand from rivers.

It's estimated that about 19 million square miles (30.5 million sq km) of planet Earth is covered by deserts. That's a lot of sand – useless sand, I might add. Meanwhile, sand that's used for concrete and mortar in construction is collected from riverbeds and riverbanks, as well as from crushing quarry stones, and digging up seafloors and pits underground. All of these sources erode or deplete environmental resources.

As such, figuring out a way to make use of desert sand could help offset the damage done to some degree. To that end, researchers from the Norwegian University of Science and Technology (NTNU) and the University of Tokyo have come up with what they're calling Botanical Sand Concrete (BSC), or Sandcrete.

"The challenge is that desert sand is so fine-grained that it is not suitable as a fastener in concrete. In other words, the concrete will not be hard enough to be used in construction projects," said Ren Wei, a postdoctoral fellow at NTNU who authored the paper on Sandcrete that appeared in the Journal of Building Engineering last November.

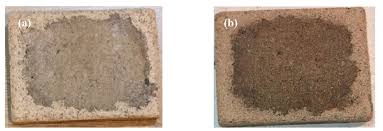

After testing a range of types of desert sand and different ways to mix it, the team figured out a recipe combining equal parts of desert sand with powdered wood at a high temperature of 356 °F (180 °C) and high pressure, using a double-plate hot-pressing machine to create blocks.

Instead of a chemical reaction with cement, Sandcrete relies on the lignin (organic polymers) found naturally in wood. Under heat and pressure, the lignin becomes soft and acts like a natural glue that binds the sand particles together. The natural alkalinity of the sand also helps this adhesive bond more effectively, resulting in a block strong enough to be used for pavement bricks, as prescribed by Japanese Industrial Standards.

Despite my opening for this story, the researchers note that Sandcrete will make the most sense when used in arid regions close to deserts, where the sand can be sourced nearby, so it doesn't incur high environmental costs of transporting it over long distances.

Smart dust technology...

Smart dust technology...