Breaking News

How a 27-Year-Old Codebreaker Busted the Myth of Bitcoin's Anonymity

How a 27-Year-Old Codebreaker Busted the Myth of Bitcoin's Anonymity

Old World Order is COLLAPSING: The Death of Europe and the Rise of China

Old World Order is COLLAPSING: The Death of Europe and the Rise of China

Energy Secretary Expects Fusion to Power the World in 8-15 Years

Energy Secretary Expects Fusion to Power the World in 8-15 Years

South Koreans Feel Betrayed Over Immigration Raid, Now Comes the Blowback

South Koreans Feel Betrayed Over Immigration Raid, Now Comes the Blowback

Top Tech News

Tesla Megapack Keynote LIVE - TESLA is Making Transformers !!

Tesla Megapack Keynote LIVE - TESLA is Making Transformers !!

Methylene chloride (CH2Cl?) and acetone (C?H?O) create a powerful paint remover...

Methylene chloride (CH2Cl?) and acetone (C?H?O) create a powerful paint remover...

Engineer Builds His Own X-Ray After Hospital Charges Him $69K

Engineer Builds His Own X-Ray After Hospital Charges Him $69K

Researchers create 2D nanomaterials with up to nine metals for extreme conditions

Researchers create 2D nanomaterials with up to nine metals for extreme conditions

The Evolution of Electric Motors: From Bulky to Lightweight, Efficient Powerhouses

The Evolution of Electric Motors: From Bulky to Lightweight, Efficient Powerhouses

3D-Printing 'Glue Gun' Can Repair Bone Fractures During Surgery Filling-in the Gaps Around..

3D-Printing 'Glue Gun' Can Repair Bone Fractures During Surgery Filling-in the Gaps Around..

Kevlar-like EV battery material dissolves after use to recycle itself

Kevlar-like EV battery material dissolves after use to recycle itself

Laser connects plane and satellite in breakthrough air-to-space link

Laser connects plane and satellite in breakthrough air-to-space link

Lucid Motors' World-Leading Electric Powertrain Breakdown with Emad Dlala and Eric Bach

Lucid Motors' World-Leading Electric Powertrain Breakdown with Emad Dlala and Eric Bach

Murder, UFOs & Antigravity Tech -- What's Really Happening at Huntsville, Alabama's Space Po

Murder, UFOs & Antigravity Tech -- What's Really Happening at Huntsville, Alabama's Space Po

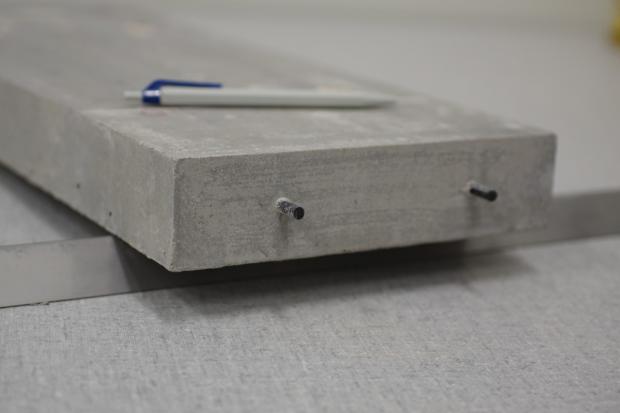

Leaner, greener, expanding concrete pre-stresses itself as it forms

A novel adaptation of this pre-stressing technique has been used to produce concrete that is lighter but with comparable strength, an advance that if widely applied, could save significant amounts of CO2.

As the most commonly used construction material in the world, the carbon footprint of concrete is massive, with the billions of tonnes produced each year requiring vast amounts of energy. For this reason, scientists all around the world are looking to tweak the production processes to make them more environmentally friendly, with even small improvements potentially having big ramifications.

The latest breakthrough comes from scientists at the Swiss Federal Laboratories for Materials Science and Technology (EMPA), where ways to improve on pre-stressed concrete technology are being investigated. This technique is often used when the material is required to withstand especially high loads, such as a beam or a bridge, with the tensioned steel tendons generating forces that compress the material from within.