Breaking News

Networks Versus Hierarchies in Minneapolis' Struggle Against ICE

Networks Versus Hierarchies in Minneapolis' Struggle Against ICE

Billionaire Reid Hoffman, Who Bankrolled the E. Jean Carroll Lawsuit Against Trump,...

Billionaire Reid Hoffman, Who Bankrolled the E. Jean Carroll Lawsuit Against Trump,...

Hybrid jet engines work to excel where pure-electric jets fail

Hybrid jet engines work to excel where pure-electric jets fail

This Could Completely Change the Way You Grade

This Could Completely Change the Way You Grade

Top Tech News

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

Lab–grown LIFE takes a major step forward – as scientists use AI to create a virus never seen be

Lab–grown LIFE takes a major step forward – as scientists use AI to create a virus never seen be

New Electric 'Donut Motor' Makes 856 HP but Weighs Just 88 Pounds

New Electric 'Donut Motor' Makes 856 HP but Weighs Just 88 Pounds

Donut Lab Says It Cracked Solid-State Batteries. Experts Have Questions.

Donut Lab Says It Cracked Solid-State Batteries. Experts Have Questions.

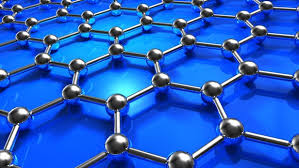

Bacteria recruited to produce graphene on the cheap

One of the main hurdles though is that it's tricky to manufacture on large scales. Now researchers at the University of Rochester have recruited bacteria to make the stuff, which is cheaper and faster than current methods and doesn't require harsh chemicals.

Graphene production has come a long way since researchers first used sticky tape to peel single-atom-thick layers off of lumps of graphite. Now it's often made by chemical vapor deposition, or by shredding graphite into graphene oxide then chemically reducing it. Both of those methods generally require the use of harsh chemicals though, leading scientists to find softer alternatives.

For the new study, the team found that a bacteria called Shewanella worked well as one such alternative.