Breaking News

Will Trump End Sham Democracy Promotions?

Will Trump End Sham Democracy Promotions?

Review: Thumb-sized thermal camera turns your phone into a smart tool

Review: Thumb-sized thermal camera turns your phone into a smart tool

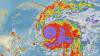

Americans stranded in Jamaica plea for help as 'worst ever hurricane' to slam Caribbean isla

Americans stranded in Jamaica plea for help as 'worst ever hurricane' to slam Caribbean isla

Urgent warning to Gmail users as 183 MILLION passwords are stolen in data breach...

Urgent warning to Gmail users as 183 MILLION passwords are stolen in data breach...

Top Tech News

Graphene Dream Becomes a Reality as Miracle Material Enters Production for Better Chips, Batteries

Graphene Dream Becomes a Reality as Miracle Material Enters Production for Better Chips, Batteries

Virtual Fencing May Allow Thousands More Cattle to Be Ranched on Land Rather Than in Barns

Virtual Fencing May Allow Thousands More Cattle to Be Ranched on Land Rather Than in Barns

Prominent Personalities Sign Letter Seeking Ban On 'Development Of Superintelligence'

Prominent Personalities Sign Letter Seeking Ban On 'Development Of Superintelligence'

Why 'Mirror Life' Is Causing Some Genetic Scientists To Freak Out

Why 'Mirror Life' Is Causing Some Genetic Scientists To Freak Out

Retina e-paper promises screens 'visually indistinguishable from reality'

Retina e-paper promises screens 'visually indistinguishable from reality'

Scientists baffled as interstellar visitor appears to reverse thrust before vanishing behind the sun

Scientists baffled as interstellar visitor appears to reverse thrust before vanishing behind the sun

Future of Satellite of Direct to Cellphone

Future of Satellite of Direct to Cellphone

Amazon goes nuclear with new modular reactor plant

Amazon goes nuclear with new modular reactor plant

China Is Making 800-Mile EV Batteries. Here's Why America Can't Have Them

China Is Making 800-Mile EV Batteries. Here's Why America Can't Have Them

Nissan Says It's On Track For Solid-State Batteries That Double EV Range By 2028

Nissan's glory days are well behind it. The automaker is trying to save itself after years of shrinking profits and sales. Its recovery plan includes layoffs, plant closures and a new wave of products, including electric vehicles and extended-range hybrids.

But even in the middle of this challenging transition, Nissan isn't giving up on future technologies. The company is still betting big on solid-state batteries, and seems on track to be one of the first automakers to bring them to the market.

The automaker has developed prototype solid-state battery cells that could double the driving range of its EVs when they enter production, Nikkei reported on Sunday. Nissan's solid-state battery cells have now reached performance targets to enter mass production, with help from U.S. battery start-up LiCAP Technologies.

The Sacramento-based start-up specializes in dry electrodes that eliminate the expensive, time-consuming wet-coating process.

Wet coating involves the mixture of active materials, conductive additives and binders with a solvent to form a liquid slurry. This cathode and anode slurry then gets coated onto current collectors made from aluminum and copper foils, which are then dried in an oven at high temperatures.

Dry coating eliminates solvent and liquid slurry by using the raw material mix to form a solid powder, which is then directly added to the current collector and flattened using roll presses, according to LG Energy Solution.

Making batteries using this dry electrode process across large factories with minimal defects is the big challenge. That's the sort of information automakers and battery companies usually closely guard to prevent rivals from edging them out.

Nissan has already been running a pilot production line for solid-state batteries since the start of this year. LiCAP Technologies also runs a 300 megawatt-hour production line in California for its proprietary Activated Dry Electrode technology.

The automaker is reportedly targeting a price of $75 per kilowatt-hour, well below last year's average pack price of $115 per kWh, according to BloombergNEF. Getting there would require economies of scale better than today's lithium-ion batteries, which already have established supply chains.

China Innovates: Transforming Sand into Paper

China Innovates: Transforming Sand into Paper