Breaking News

The Cost Of Living The American Dream For A Lifetime Has Reached A Whopping 5 Million Dollars

The Cost Of Living The American Dream For A Lifetime Has Reached A Whopping 5 Million Dollars

Reverse Erectile Dysfunction FAST (Without Viagra)

Reverse Erectile Dysfunction FAST (Without Viagra)

Who's Buying Up America's Farmland? The Land Grab You Need to Know About

Who's Buying Up America's Farmland? The Land Grab You Need to Know About

Corruption, Propaganda & TikTok Brainwashing -- Rep. Thomas Massie Tells All

Corruption, Propaganda & TikTok Brainwashing -- Rep. Thomas Massie Tells All

Top Tech News

Methylene chloride (CH2Cl?) and acetone (C?H?O) create a powerful paint remover...

Methylene chloride (CH2Cl?) and acetone (C?H?O) create a powerful paint remover...

Engineer Builds His Own X-Ray After Hospital Charges Him $69K

Engineer Builds His Own X-Ray After Hospital Charges Him $69K

Researchers create 2D nanomaterials with up to nine metals for extreme conditions

Researchers create 2D nanomaterials with up to nine metals for extreme conditions

The Evolution of Electric Motors: From Bulky to Lightweight, Efficient Powerhouses

The Evolution of Electric Motors: From Bulky to Lightweight, Efficient Powerhouses

3D-Printing 'Glue Gun' Can Repair Bone Fractures During Surgery Filling-in the Gaps Around..

3D-Printing 'Glue Gun' Can Repair Bone Fractures During Surgery Filling-in the Gaps Around..

Kevlar-like EV battery material dissolves after use to recycle itself

Kevlar-like EV battery material dissolves after use to recycle itself

Laser connects plane and satellite in breakthrough air-to-space link

Laser connects plane and satellite in breakthrough air-to-space link

Lucid Motors' World-Leading Electric Powertrain Breakdown with Emad Dlala and Eric Bach

Lucid Motors' World-Leading Electric Powertrain Breakdown with Emad Dlala and Eric Bach

Murder, UFOs & Antigravity Tech -- What's Really Happening at Huntsville, Alabama's Space Po

Murder, UFOs & Antigravity Tech -- What's Really Happening at Huntsville, Alabama's Space Po

3D-Printing 'Glue Gun' Can Repair Bone Fractures During Surgery Filling-in the Gaps Around..

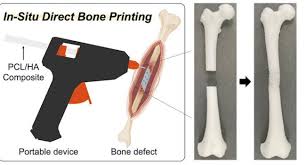

A new 3D printing "glue gun" can generate bone grafts directly onto fractures, using a revolutionary process that can fill-in the gaps around the site's jagged edges.

Now, the researchers in South Korea are preparing for human trials, having developed a tool made from a modified glue gun that can 3D-print bone grafts to repair defects during surgery.

Essentially, it quickly creates bone implants on the spot, without the need for making them in advance.

The researchers "optimized" the 3D-printed grafts until they exhibited high structural flexibility while releasing anti-inflammatory antibiotics and promoting natural bone regrowth at the grafting site—conforming to the jagged edges of a fracture.

Bone implants have previously been made of metal or donor bone or, more recently, 3D-printed material. But in cases involving more complex fractures the implants must be designed and produced prior to surgery to allow for appropriate fitting.

So, the scientists developed a new technology that offers a distinct approach: a printing system for use directly at the surgical site, that enables a "real-time fabrication and application of a scaffold," said study co-author Professor Jung Seung Lee, of Sungkyunkwan University in South Korea.

"This allows for highly accurate anatomical matching even in irregular or complex defects without the need for preoperative preparation such as imaging, modeling, and trimming processes."

What's in the 'glue'?

He explained that the material fed into the glue gun is a filament comprised of two major components: a feature of natural bone known to promote healing called hydroxyapatite (HA) and a biocompatible thermoplastic called polycaprolactone (PCL).

PCL can liquify in temperatures as low as 60 Celsius, which when applied with a heat-modified glue gun, is cool enough to prevent tissue damage during surgical application while being able to conform to the jagged grooves of fractured bone.

Tiny briefcase engine boosts EV range beyond battery power

Tiny briefcase engine boosts EV range beyond battery power