Breaking News

Palantir kills people? But Who's Really Pushing the Buttons?

Palantir kills people? But Who's Really Pushing the Buttons?

'Big Short' investor Michael Burry sounds alarm on AI bubble that's 'too big to save

'Big Short' investor Michael Burry sounds alarm on AI bubble that's 'too big to save

2026-01-21 -- Ernest Hancock interviews Professor James Corbett (Corbett Report)

2026-01-21 -- Ernest Hancock interviews Professor James Corbett (Corbett Report)

Joe rogan reacts to the Godfather of Ai Geoffrey Hinton talk of his creation

Joe rogan reacts to the Godfather of Ai Geoffrey Hinton talk of his creation

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

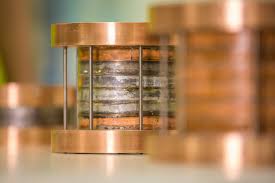

Tokamak Energy Has 24.4 Tesla High Temperature Superconducting Magnets...

The magnet is wound from REBCO (Rare earth – Barium – Copper Oxide) HTS tape. This conduction-cooled all-REBCO magnet achieved its peak field at 21K in a cold bore of 50 mm, which we believe to be record performance. In superconducting terms, 21K is a relatively high temperature. Additionally, the magnet is extremely robust, reliable and simple to manufacture. The engineers have been impressed by the defect tolerance of the coils and their response to a sudden loss of superconductivity, called a quench.

The achievement is an important milestone on the route to commercial fusion energy because high magnetic fields are necessary for tokamak machines to trap the hot fusion fuel, which is in the form of an electrically-charged gas called plasma. High temperature superconducting materials will facilitate the higher magnetic fields necessary for efficient commercial fusion reactors.

The progress of the HTS team has been faster than expected with milestones being hit well ahead of schedule (this milestone was scheduled for late 2020). The next step is to scale up these magnets into the configuration required for tokamaks.

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market