Breaking News

Palantir kills people? But Who's Really Pushing the Buttons?

Palantir kills people? But Who's Really Pushing the Buttons?

'Big Short' investor Michael Burry sounds alarm on AI bubble that's 'too big to save

'Big Short' investor Michael Burry sounds alarm on AI bubble that's 'too big to save

2026-01-21 -- Ernest Hancock interviews Professor James Corbett (Corbett Report) MP3&4

2026-01-21 -- Ernest Hancock interviews Professor James Corbett (Corbett Report) MP3&4

Joe rogan reacts to the Godfather of Ai Geoffrey Hinton talk of his creation

Joe rogan reacts to the Godfather of Ai Geoffrey Hinton talk of his creation

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

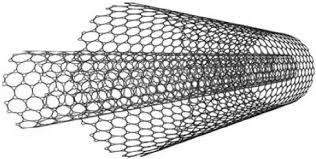

Fabrication of Ultrastrong 700 Gigapascal Fused Double-walled Carbon Nanotubes

Fused double-walled carbon nanotube (DWNT) fibers were made with a strength of a 700 GPa Young's modulus. This strength was seen in prior experiments, in 2010 and 2011, where electron beams welded DWNTs in microscopic bundles together and the fused bundles had 700 GPa tensile strength. There is now an effort to scale up production of ultrahigh strength material using high temperatures (1700-2300 C) and about 800 atmospheres of pressure instead of an expensive and time-consuming process using high-voltage e-beams. The electron dose available from commercial e-beam facilitaties is so low that processing macroscopic DWNT materials would take months instead of half an hour or less. The same thermal treatment process will enable manufacturing wires that have the highest conductivity of all carbon nanotube wires.

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market