Breaking News

Palantir kills people? But Who's Really Pushing the Buttons?

Palantir kills people? But Who's Really Pushing the Buttons?

'Big Short' investor Michael Burry sounds alarm on AI bubble that's 'too big to save

'Big Short' investor Michael Burry sounds alarm on AI bubble that's 'too big to save

2026-01-21 -- Ernest Hancock interviews Professor James Corbett (Corbett Report) MP3&4

2026-01-21 -- Ernest Hancock interviews Professor James Corbett (Corbett Report) MP3&4

Joe rogan reacts to the Godfather of Ai Geoffrey Hinton talk of his creation

Joe rogan reacts to the Godfather of Ai Geoffrey Hinton talk of his creation

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

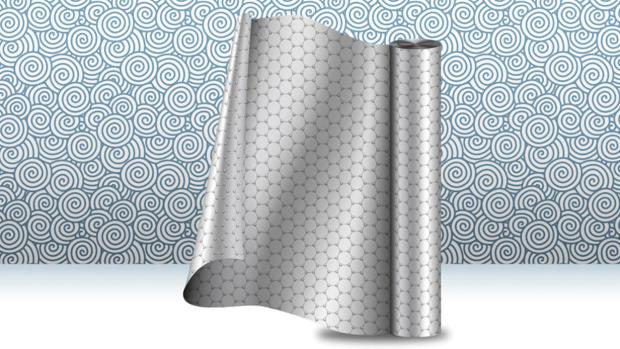

MIT researchers develop scalable manufacturing process for graphene sheets

Graphene is an ultra-light, ultra-strong, super conductive, transparent carbon allotrope that resembles a chicken wire lattice at the atomic level, one that makes it impervious to even the tiniest of atoms – helium. Thus, with the right-sized holes poked in it, it can be tailored to filter out specific molecules very effectively.

The problem has always been manufacturing the damn stuff, particularly at any kind of scale, because graphene needs to be grown under very particular conditions. And that's what an MIT team believes it's cracked, using a roll-to-roll approach that's already producing up to 10 m (33 ft) of continuous graphene at a time, at a rate of 5 cm (2 in) per minute.

The process uses chemical vapour deposition, spooling a length of copper foil between two rolls and passing it slowly through two tubes. The first tube heats the foil to an ideal temperature, and in the second, a specific ratio of methane and hydrogen gas is pumped in. When this gas mixture hits the heated foil, graphene begins to form.

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market