Breaking News

RAY DALIO SAYS THE MONETARY ORDER IS BREAKING DOWN...

RAY DALIO SAYS THE MONETARY ORDER IS BREAKING DOWN...

2026 - The Year US Hegemony Ends?

2026 - The Year US Hegemony Ends?

Censorship Lawsuit Big Tech Hoped Wouldn't Happen

Censorship Lawsuit Big Tech Hoped Wouldn't Happen

House Oversight Panel votes to advance contempt resolutions against the Clintons

House Oversight Panel votes to advance contempt resolutions against the Clintons

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

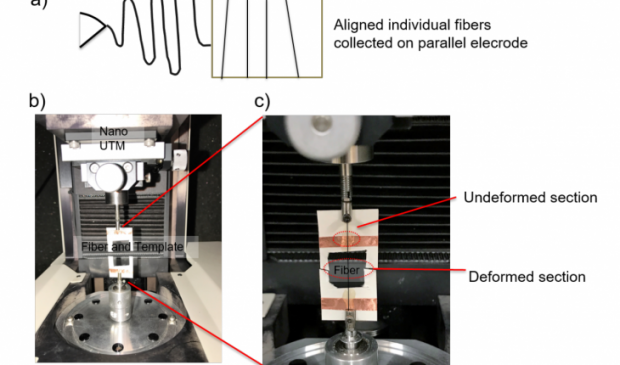

Stronger and tougher fiber created by MIT

Journal of Material Science – Ultrafine high performance polyethylene fibers

Abstract

Stiff, strong and tough ultrafine polyethylene fibers that rival the best high-performance fibers, but with diameters less than one micron, are fabricated for the first time by "gel-electrospinning." In this process, solution concentration and process temperatures are chosen to induce the formation of gel filaments "in flight," which are subsequently drawn at high rates as a consequence of the whipping instability. The resulting submicron-diameter fibers exhibited Young's moduli of 73 ± 13 GPa, yield strengths of 3.5 ± 0.6 GPa, and toughnesses of 1.8 ± 0.3 GPa, on average. Among the smallest fibers examined, one with a diameter of 490 ± 50 nm showed a Young's modulus of 110 ± 16 GPa, ultimate tensile strength of 6.3 ± 0.9 GPa, and toughness of 2.1 ± 0.3 GPa, a combination of mechanical properties that is unparalleled among polymer fibers to date. The correlation of stiffness, strength and toughness with fiber diameter is attributed to high crystallinity and crystallite orientation, combined with fewer defects and enhanced chain slip associated with small diameter and high specific surface area. Gel-electrospinning improves the prospects for production of such fibers at scale.

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market