Breaking News

Poland to Buy 150 Tons More Gold, Approves up to 36.6% Held

Poland to Buy 150 Tons More Gold, Approves up to 36.6% Held

Michael Oliver: T-Bond Nuclear Panic Will Send Silver VIOLENTLY to $300–$500 | Gold to $8,000

Michael Oliver: T-Bond Nuclear Panic Will Send Silver VIOLENTLY to $300–$500 | Gold to $8,000

Greentanamo: Trump Deal Gives US Sovereignty Over Small Pockets Of Greenland For Military Bases

Greentanamo: Trump Deal Gives US Sovereignty Over Small Pockets Of Greenland For Military Bases

Das: Trump's Spat With The Fed Is Not About Central Bank Independence

Das: Trump's Spat With The Fed Is Not About Central Bank Independence

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

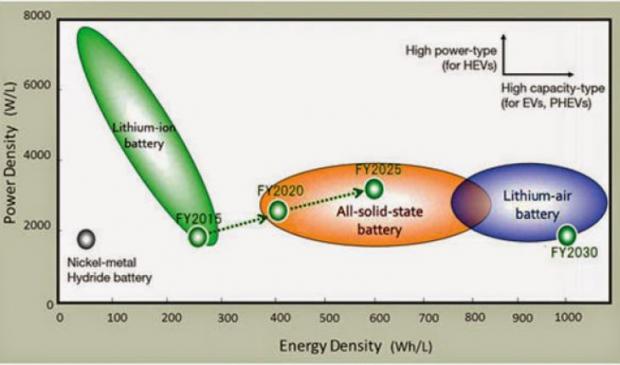

Dyson will spend about $3 billion to make solid state battery electric car by 2020

Dyson recently spent $90 million to buy University of Michigan spinoff Sakti3. Sakti3's solid state battery technology is potentially smaller, safer, more reliable and longer-lasting than the most advanced lithium-ion batteries on the market today.

The Dyson electric car team already has a staff of over 400 and they are recruiting aggressively.

Sakti3, Inc. (sakti3.com) announced that in mid-2014 that they had produced a battery cell on fully scalable equipment with over 1100 Watt hours per liter (Wh per l) in volumetric energy density. This translates to more than double the usage time in a wearable device like a smartwatch, from 3.5 h to more than 9 h. It also translates to almost double the range in an EV like the Tesla Model S, from 265 mi to 480 mi.

Sakti3 reports that it demonstrated over 1000 Wh per l in 2012, and has since moved to a pilot tool, using all scalable materials and equipment. The technology development was guided by mathematical simulations, starting with materials, and continuing to full scale plant layout to avoid any high cost materials, equipment or processes.

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market