Breaking News

Poland to Buy 150 Tons More Gold, Approves up to 36.6% Held

Poland to Buy 150 Tons More Gold, Approves up to 36.6% Held

Michael Oliver: T-Bond Nuclear Panic Will Send Silver VIOLENTLY to $300–$500 | Gold to $8,000

Michael Oliver: T-Bond Nuclear Panic Will Send Silver VIOLENTLY to $300–$500 | Gold to $8,000

Greentanamo: Trump Deal Gives US Sovereignty Over Small Pockets Of Greenland For Military Bases

Greentanamo: Trump Deal Gives US Sovereignty Over Small Pockets Of Greenland For Military Bases

Das: Trump's Spat With The Fed Is Not About Central Bank Independence

Das: Trump's Spat With The Fed Is Not About Central Bank Independence

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

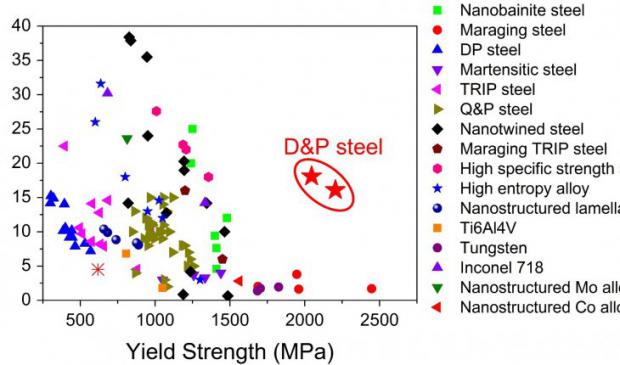

Breakthrough steel is far stronger, lower cost and process is applicable to Titanium

However, in some particular high-loading structural applications, metallic materials shall also have large ductility and high toughness to facilitate the precise forming of structural components and to avoid the catastrophic failure of components during service. Unfortunately, increasing strength often leads to the decrease in ductility, which is known as the strength-ductility trade-off. For example, ceramics and amorphous materials have negligible ductility, although they have great hardness and ultra-high strength. To simultaneously increase both strength and ductility of metallic materials using conventional industrial processing routes is both of great scientific and technological importance and is yet quite challenging in both the materials science community and industry sectors.

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market