Breaking News

Is The Government Coming For Our Seeds?

Is The Government Coming For Our Seeds?

Looming ice storm could be among worst on record

Looming ice storm could be among worst on record

The walls are actually closing in on Ilhan Omar and her husband…

The walls are actually closing in on Ilhan Omar and her husband…

Tesla and XAI's Digital Agent Strategy

Tesla and XAI's Digital Agent Strategy

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

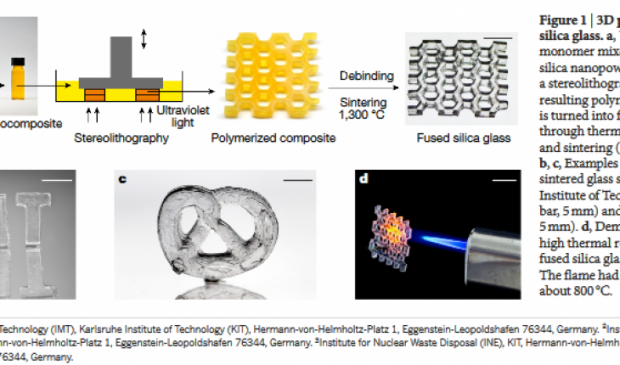

3D printing of glass with precision of tens of microns

As a consequence of the properties of glass, such as transparency, thermal stability and resistance to acids, the use of this material in 3D-printing opens up manifold new applications in production and research, such as optics, data transmission, and biotechnology.

The scientists mix nanoparticles of high-purity quartz glass and a small quantity of liquid polymer and allow this mixture to be cured by light at specific points – by means of stereolithog-raphy. The material, which has remained liquid, is washed out in a solvent bath, leaving only the desired cured structure. The polymer still mixed in this glass structure is subsequently removed by heat-ing.

"The shape initially resembles that of a pound cake; it is still unstable, and therefore the glass is sintered in a final step, i.e. heated so that the glass particles are fused," explains Rapp.

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market