Breaking News

Brand New Solar Battery With THIS Amazing Feature! EG4 314Ah Wall Mount Review

Brand New Solar Battery With THIS Amazing Feature! EG4 314Ah Wall Mount Review

This New Forecast Just Got WAY Worse...

This New Forecast Just Got WAY Worse...

S3E4: The Freedom Movement Funded Its Own Prison

S3E4: The Freedom Movement Funded Its Own Prison

Dan Bongino Gets DESTROYED By Dave Smith & Ducks Debate!

Dan Bongino Gets DESTROYED By Dave Smith & Ducks Debate!

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

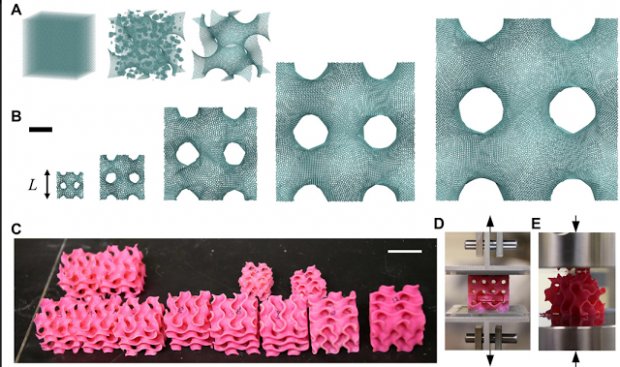

MIT makes compressed graphene sponge material that is 20 times less dense...

A team of researchers at MIT has designed one of the strongest lightweight materials known, by compressing and fusing flakes of graphene, a two-dimensional form of carbon. The new material, a sponge-like configuration with a density of just 5 percent, can have a strength 10 times that of steel.

In its two-dimensional form, graphene is thought to be the strongest of all known materials. But researchers until now have had a hard time translating that two-dimensional strength into useful three-dimensional materials.

The new findings show that the crucial aspect of the new 3-D forms has more to do with their unusual geometrical configuration than with the material itself, which suggests that similar strong, lightweight materials could be made from a variety of materials by creating similar geometric features.

Highlights

* light as stryofoam but stronger than steel

* 20 times less dense than steel but 10 times stronger

* could lead to a replacement for helium for strong yet light dirigible applications

* bringing 2D strength of graphene to 3D materials

* new range of lightness and strength combinations for different applications

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market