Breaking News

The Pentagon Failed Its Audit Again. You Should Be Alarmed.

The Pentagon Failed Its Audit Again. You Should Be Alarmed.

Cuban Crisis 2.0. What if 'Gerans' flew from Cuba?

Cuban Crisis 2.0. What if 'Gerans' flew from Cuba?

Senate Democrats Offer Promising Ideas for Changing Immigration Enforcement

Senate Democrats Offer Promising Ideas for Changing Immigration Enforcement

Never Seen Risk Like This Before in My Career

Never Seen Risk Like This Before in My Career

Top Tech News

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

Lab–grown LIFE takes a major step forward – as scientists use AI to create a virus never seen be

Lab–grown LIFE takes a major step forward – as scientists use AI to create a virus never seen be

New Electric 'Donut Motor' Makes 856 HP but Weighs Just 88 Pounds

New Electric 'Donut Motor' Makes 856 HP but Weighs Just 88 Pounds

Donut Lab Says It Cracked Solid-State Batteries. Experts Have Questions.

Donut Lab Says It Cracked Solid-State Batteries. Experts Have Questions.

Engineers Create Diesel From Water And Carbon Dioxide That Has Zero-Carbon Footprint

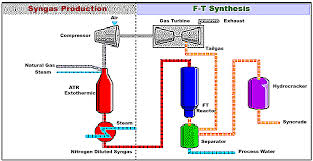

Utilizing the Fischer-Tropsch process, an underutilized technique which has been around since the 1920's, Audi engineers were able to produce a clean-burning diesel fuel. Not only is the fuel carbon neutral, it can be poured directly into current cars of today without modifying the machinery.

The German car manufacturer announced in 2015 that it had successfully created an "e-diesel," or diesel containing ethanol, by using renewable energy to produce a liquid fuel using nothing more than water and carbon dioxide. With fuel prices on the rise once again, the news has gone viral for understandable reasons.

It took just four months for a plant in Dresden operated by clean tech company Sunfire to produce results using the Fischer-Tropsch process. The fuel, named "blue crude," is composed of long-chain hydrocarbon compounds. While it is similar to fossil fuels, it is free from sulfur and aromatics, therefore, burns soot-free.

The engineers' success can be attributed to the high temperatures used. The first step to create this eco-friendly diesel fuel is to harness renewable energy through solar, wind and/or hydropower. Then, engineers heat water to temperatures in excess of 800oC (1472oF). The steam gets broken down into oxygen and hydrogen through high-temperature electrolysis – a process where an electric current is passed through a solution, reports IFLScience. Once hydrogen is removed, it is mixed with carbon monoxide under high heat and pressure. This results in the formation of the hydrocarbon product they're calling "blue crude."

Credit: fostertire.blogspot.com