Breaking News

How Do Dumb People or Corrupt People Get Elected to Top Positions?

Brand New Solar Battery With THIS Amazing Feature! EG4 314Ah Wall Mount Review

Brand New Solar Battery With THIS Amazing Feature! EG4 314Ah Wall Mount Review

This New Forecast Just Got WAY Worse...

This New Forecast Just Got WAY Worse...

S3E4: The Freedom Movement Funded Its Own Prison

S3E4: The Freedom Movement Funded Its Own Prison

Top Tech News

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

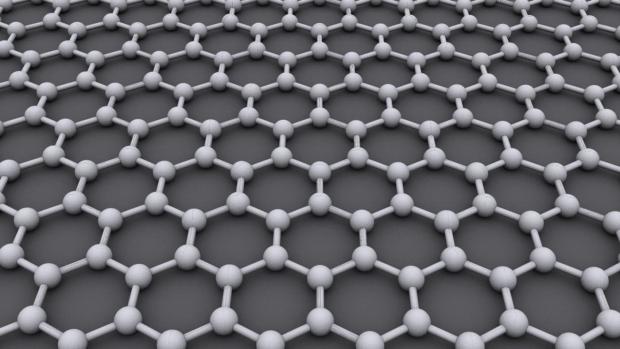

Adding silicon-sulfur into 3D graphene makes for game-changing battery potential

Chemists have long known that lithium-sulfur has huge potential as a next-generation battery solution, combining the strengths of a fuel cell (very energy dense) with the strengths of a battery (self-contained energy storage) – all in a package that is extremely environmentally-friendly and that has a low cost of manufacture.

The problem is that cathodes of sulfur and lithium have lots of material loss due to the solubility of polysulfides, and are not often efficient because sulfur has insulative properties rather than conductive. Arranging the sulfur in the lithium mix via various methods has previously shown promise, but has strict limits that have so far not allowed Li-S batteries to be viable for commercialization.

Various attempts to control the sulfur within the lithium mix have usually centered on porous carbons (usually activated carbon) for macroporous, mesoporous, and microporous solutions to make carbon-sulfur hybrids. These have worked, to a point, but have restricted pore volumes and thus limited viability. Likewise, sulfur copolymers have been a promising choice, but still have conductivity issues.

Nano Nuclear Enters The Asian Market

Nano Nuclear Enters The Asian Market