Breaking News

The 3 Reasons Behind US Plot to Depose Venezuela's Maduro – Video #254

The 3 Reasons Behind US Plot to Depose Venezuela's Maduro – Video #254

Evangelicals and the Veneration of Israel

Evangelicals and the Veneration of Israel

Zohran Mamdani's Socialist Recipe for Economic Destruction

Zohran Mamdani's Socialist Recipe for Economic Destruction

BREAKING: Fed-Up Citizens Sue New York AG Letitia James for Voter Intimidation...

BREAKING: Fed-Up Citizens Sue New York AG Letitia James for Voter Intimidation...

Top Tech News

HUGE 32kWh LiFePO4 DIY Battery w/ 628Ah Cells! 90 Minute Build

HUGE 32kWh LiFePO4 DIY Battery w/ 628Ah Cells! 90 Minute Build

What Has Bitcoin Become 17 Years After Satoshi Nakamoto Published The Whitepaper?

What Has Bitcoin Become 17 Years After Satoshi Nakamoto Published The Whitepaper?

Japan just injected artificial blood into a human. No blood type needed. No refrigeration.

Japan just injected artificial blood into a human. No blood type needed. No refrigeration.

The 6 Best LLM Tools To Run Models Locally

The 6 Best LLM Tools To Run Models Locally

Testing My First Sodium-Ion Solar Battery

Testing My First Sodium-Ion Solar Battery

A man once paralyzed from the waist down now stands on his own, not with machines or wires,...

A man once paralyzed from the waist down now stands on his own, not with machines or wires,...

Review: Thumb-sized thermal camera turns your phone into a smart tool

Review: Thumb-sized thermal camera turns your phone into a smart tool

Army To Bring Nuclear Microreactors To Its Bases By 2028

Army To Bring Nuclear Microreactors To Its Bases By 2028

Nissan Says It's On Track For Solid-State Batteries That Double EV Range By 2028

Nissan Says It's On Track For Solid-State Batteries That Double EV Range By 2028

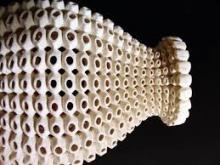

3D-Printed Ceramics Could Build Next-Gen Spaceships

Heat-shielding tiles on the space shuttle were made from ceramics, for example.

Now researchers have used a 3D printer to make customized ceramic parts that have also overcome the Achilles' heel of ceramic objects: their tendency to crack.

The finding could open the door to a new class of ceramic-body or ceramic-engine jets, perhaps even a hypersonic craft that can fly from New York to Tokyo in a few hours.

"If you go very fast, about 10 times speed of sound within the atmosphere, then any vehicle will heat up tremendously because of air friction," said Tobias Schaedler, senior scientist at HRL Laboratories in Malibu, Calif. "People want to build hypersonic vehicles and you need ceramics for the whole shell of the vehicle."

Schaedler and colleagues at HRL invented a resin formulation that can be 3-D printed into parts of virtually any shape and size.

Carbon based computers that run on iron

Carbon based computers that run on iron